Final PDF Poster Submission must be received by 24 April 2026 for consideration.

Poster SubmissionTimeline

-

Final PDF Poster Submission Date

24 April 2026

Deadline for final printable PDF submission

Each abstract must include the following information to be considered:

- Presentation Title

- Presenter's Name And Contact Details

-

Presenter's Biography

(Approx. 100 words) -

Additional Speakers

(If applicable) - Key Objectives of Topic

-

2-3 Paragraph Abstract, Summarizing the Topic

(Max 200 words)

General Information

Abstract submitters may submit up to two entries for consideration.

All presentations must be free of commercial intent. Incomplete proposals will not be considered.

Call for Posters/Case Studies

Types of Submissions

Poster

Accepted posters will:

- Be displayed in the exhibit hall and might be a part of the guided poster walk

Get the Attention you deserve!

Maximize your visibility by contributing a podium or poster presentation at PDA Good Aseptic Manufacturing Conference 2026. Leverage this unique opportunity to highlight your work at the event. Posters will be available online post-event.

Topics we are looking for:

- 1. Pharmaceutical Quality System

- Quality Risk Management

- Role of Quality Assurance Personnel

- Quality on the Shop Floor/Quality Oversight

- Deviation Handling, Root Cause Investigation

- Corrective and Preventive Actions (CAPA)

- Continuous Improvement and Change Control

- Management of Non-Conformities

- Phase-Appropriate Aseptic Processing

- Experience and Expectations from Regulatory Inspections

- Regulatory Feedback from EMA, U.S. FDA, PIC/S, WHO, etc.

- Case Studies Based on Recall Analysis

- 2. Contamination Control Strategy (CCS)

- Microbial, Endotoxin, and Particle Control

- Process Knowledge and CCS Effectiveness

- CCS Integration into the PQS

- Environmental and Process Monitoring/Trending

- In-Process Controls

- Digital Tools Supporting CCS

- Operator Support, Behavior, and Training

- Metrics and Implementation to Change and Deviation Management

- Cross-Contamination Control Strategy

- Material Transfer Concept

- Product-Specific CCS

- CCS for API and Incoming Material, PPM, etc.

- 3. Premises and Barrier Systems

- Cleanroom and Facility Design

- Quality by Design Principles

- RABS vs. Isolators

- Hydrogen Peroxide Decontamination - Cycle Development and Validation

- Air Flow Visualization/Computational Fluid Dynamics (CFD) Simulations

- First Air and Airflow Considerations

- Glove Integrity Testing

- Reduction of Interventions

- Gloveless Isolators

- Cleanroom Classification/Qualification (EN ISO 14644)

- Product-Type-Specific Design Guidance

- Material Transfer Process and Qualification (Limitations and Best Practices, e.g., Filling Line Equipment & RTU)

- EU GMP Annex 1 Affecting Legacy Facilities and Equipment

- RTU and Transfer Technologies (e.g., No-Touch Transfer E-Beam, Hydrogen Peroxide)

- Cleaning, Disinfection, and Sterilization (including Validation)

- Sterilization of Indirect Product Contact Parts

- 4. Equipment and Utilities

- Robotics and Automated Solutions

- Smart Manufacturing and Aseptic Filling Automation

- Equipment for Transfer and Utilities (Limitations and Best Practices)

- Utility System Design

- 5. Personnel

- Aseptic Quality Culture

- Qualification, Monitoring, and Training

- Digital and VR Training Modalities

- Personnel Transfer and Access Limitation

- Gowning (e.g., Overalls, Socks, Goggles)

- 6. Environmental Monitoring and Quality Control

- AI in QC Workflow

- Rapid/Advanced Methods

- Real-Time Monitoring (e.g., BFPC)

- Bioburden and Sterility Testing

- Enzymatic/Biological Indicators (including VPHP)

- Data Trending and Handling

- Viable and Nonviable Particle Measurement

- QC for Small Batch Sizes

- 7. Aseptic Process Simulation (APS)

- Aseptic Manipulations/Interventions/Reduction Strategies

- Risk-Based APS Design

- High-Risk Interventions

- Small vs. Larger Batch Size/Sample Size Considerations

- Campaign-Style Aseptic Process Simulation

- Bracketing & Matrixing Approaches

- Continuous Process Validation

- Number and Parameters for Successful Validation

- Operator Training and Qualification

- End of Production APS

- 8. Manufacturing

- Raw Material and Component Shortages

- Cost Pressure and Affordability

- Patient Benefit vs. Manufacturing Cost

- Filtration and PUPSIT

- Container Closure Systems and Integrity

- Manual Intervention Reduction

- Aseptic and Closed Systems

- Lyophilization

- Blow-Fill-Seal/Form-Fill-Seal

- EU GMP Annex 1 for New Modalities

- Manufacturing of Small-Batch (Personalized) Pharmaceuticals

- EU GMP Annex 1 for Manufacturing of HPAPIs, e.g., ADCs

- Supply Chain Logistics

- Technological Flexibility/Agile Equipment

- 9. Partnering and Cooperation

- CDMO and Sponsor Collaboration

- Small vs. Large Organization Challenges

- Quality Agreements and Systems

- Outsourcing and Project Management

- Technology Transfer

- GMP Compliance Responsibilities

- Regulatory Oversight of CDMOs

- Supply Chain Considerations under EU GMP Annex 1

- 10. Sustainability in Aseptic Manufacturing

- Impact of AI Usage on Sustainability

- Profitable Economy: Growth by Quality - Degrowth by Quantity

- Sustainability vs. Quality Assurance

- Eco-Design for Facilities and Equipment

- Life Cycle Assessment and Eco-Balancing

- Disposal and Bio-Waste Treatment

- Implication of PFAS/Plastics Control

- Water, Energy, Waste Reduction

- Reduction of Wastewater

- Cleaning for Re-Use

- Reverse Manufacturing/Disassembly

- Equipment Lifetime Extension

- Circular Economy in Manufacturing

- Sustainable Packaging and Material Selection

- EU Packaging Waste Regulation

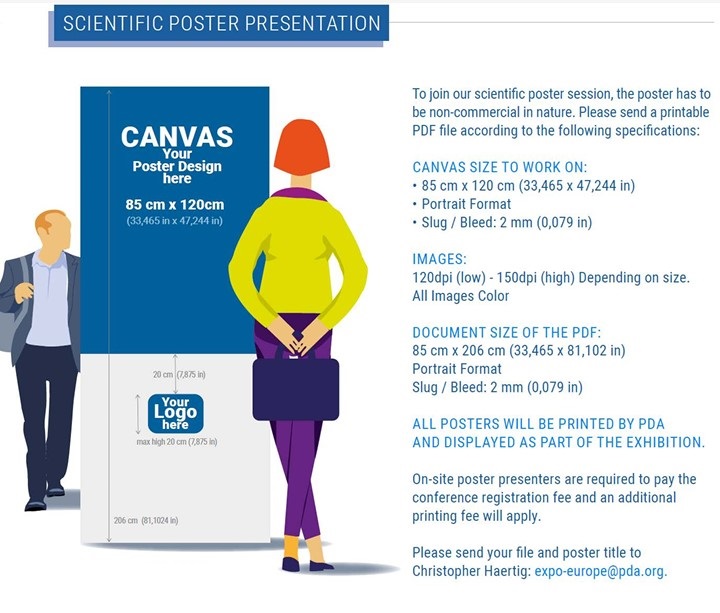

Poster Information

All posters will be printed by PDA and displayed as part of the exhibition.

Please send your final printable PDF file and poster title to expo-europe@pda.org.

Important

Poster presenters are required to pay a full conference registration fee.

Join our guided poster walk in our exhibition hall and gain more visibility. You will have the chance to engage with our audience!

Poster Display Dimensions

Please find the PDF dimension requirements below:

Exhibition and Sponsorship Opportunities

PDA is seeking vendors who provide products/services in support of this conference. Space on-site is limited and is on a first-come, first-serve basis.

Exhibition: 11-12 June 2026

To reserve your space, please contact Christopher Leisterer-Haertig at expo-europe@pda.org.