Don’t Miss the 2023 PDA Good Aseptic Manufacturing Conference!

Besides the daily challenges our companies face, we must come into compliance with the new EU GMP Annex 1: Manufacture of Sterile Medicinal Products in our current and future operations. This year, the PDA Good Aseptic Manufacturing Conference planning committee has made great progress preparing an impressive program that will focus on the impact and solutions for implementing Annex 1.

The European Commission published its first draft of Annex 1 in 2017, which was open to the public for comment. The industry was positively reactive, and more than 6,000 comments were addressed during the first round of review. Just as many were provided during the second comment phase in 2020, resulting in the document increasing in size from 16 to 58 pages.

Intensive debates have already reinforced collaborations within the industry. We first want to acknowledge the efforts of the industry, the regulatory bodies, including WHO and PIC/S, and the suppliers to deliver much more state-of-the-art guidance on the manufacture of sterile products.

For instance, the general concept behind Annex 1 is for manufacturers to move forward to closed systems and state-of-the-art and innovative technologies with robust contamination control strategies (CCS). They can then apply the agile annual update by identifying sources of improvements for design, execution and monitoring elements.

The objective of a holistic CCS is to move away from sterility-reliance based on just any terminal process or final product test and move toward a detailed, process knowledge of all potential sources of contamination. There is a long list of elements to be considered, starting with the plant and process design, and ending with corrective and preventive actions. Of course, the manufacturer might already have control systems in place, which will not need to be replaced but will need to be referenced in the CCS.

Though it will come into force in August 2023, after a one-year transition period, it is evident that the current version of Annex 1 will provide the basis for the inspection of sterile products and components intended to be used in sterile drug manufacture.

Currently, all manufacturers are assessing their current processes and equipment and planning how to comply with all new provisions, such as:

- Use of single-use systems in the manufacture of sterile products and addressing answers to provide integrity, and no interaction with drug products (e.g., extractables and leachables)

- Use of pre-use post-sterilization tests (PUPSIT) in sterile filtration application where Annex 1 provides greater details on validation

- Applicability of point-of-fill filtration as close as possible to the filling point, depending on the product to fill

- Implementation of duplex probes to obtain independent monitoring versus control for sterilization processes

- Reduction of shape and length to qualify nonviable particle-count tubing

- Autoclaving and how to perform rapid transfer of indirect parts before isolator VHP cycles

- Application of new notions on cleaning validation

- Frequency of adapted room requalification

- Efficient organization of qualification and requalification of operators in manual filling operations through aseptic process simulation

- Securing and demonstrating integrity of filling lines from the depyrogenation tunnel up to container-closure

While in the past, the pharmaceutical industry was often considered “conservative,” we are now trending to take the benefits coming from recent innovative technologies and are ready to take the next step toward a more sustainable, cost-efficient industry.

Process analytical technologies, robotization, real-time monitoring, artificial intelligence and augmented reality applications are all developments in progress that will revolutionize our industry, and we should expect such implementation of robust innovation moving forward.

PDA aims to remain one of the leading associations to emulate and inspire on all of those subjects.

On 23–24 May 2023, we hope to see many of you at the 2023 PDA Good Aseptic Manufacturing Conference in Leipzig, Germany, where we will review the latest developments through a recognized panel of speakers.

Many of the topics that will be addressed are:

- Voice of the regulatory bodies

- Practical cases on CCS implementation

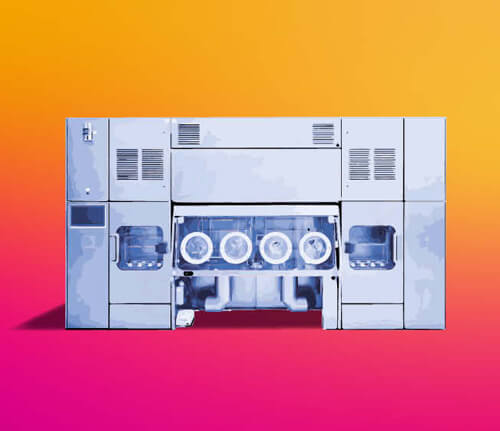

- Recent trends and development in barrier systems

- Practical implementation of new filling lines coping with Annex1 requirements

- PUPSIT to complement Annex 1

- Faster release on containers using rapid microbial method

- Current record on real-time environment monitoring

- Current record on operators aseptic training program, how to account for the human factor and how to facilitate short and efficient training periods for new personnel

- Sterilization alternative decontamination processes, VHP cycle development and validation time reduction

You are also invited to discuss practical realization by making an additional site visit at IDT Biologika on 25 May.

We look forward to seeing you in Leipzig!

Kerstin Wilken, PhD, joined IDT in January 2020 as Head of Portfolio Coordination. Wilken started her career at Vibalogics GmbH as Project Manager, and from 2017 to 2019 she served as Director of Programs & Education for PDA GmbH. Wilken also holds a PhD in biology from the Eberhard Karls University in Tübingen and is certified as Project Management Professional from PMI.

Kerstin Wilken, PhD, joined IDT in January 2020 as Head of Portfolio Coordination. Wilken started her career at Vibalogics GmbH as Project Manager, and from 2017 to 2019 she served as Director of Programs & Education for PDA GmbH. Wilken also holds a PhD in biology from the Eberhard Karls University in Tübingen and is certified as Project Management Professional from PMI. Paul Devuyst is Senior Manager Aseptic Technologies at GSK. He holds a master’s degree in bioengineer and in pharmaceutical engineering from UCLouvain (Belgium). He is an expert in engineering and project management, and he acts as global SME for GSK vaccines in secondary aseptic technologies (from formulation to vials, syringes, tubes, BFS – in RABS, Isolators up to loading / unloading of Freeze-dryers and capping steps).

Paul Devuyst is Senior Manager Aseptic Technologies at GSK. He holds a master’s degree in bioengineer and in pharmaceutical engineering from UCLouvain (Belgium). He is an expert in engineering and project management, and he acts as global SME for GSK vaccines in secondary aseptic technologies (from formulation to vials, syringes, tubes, BFS – in RABS, Isolators up to loading / unloading of Freeze-dryers and capping steps).