Industry Eyes Future of Visual Inspection Five Critical Areas of Concern Draw Attention of Pharma Industry

It goes without saying that visual inspection is critical to parenteral manufacturing. All units produced must be inspected to ensure a high level of quality assurance. Visual inspection can be performed with the human eye by a trained inspector under controlled conditions or via automation using advanced camera and computer technology.

Because visual inspection is a vital function of any manufacturing process, keeping current with advancements in technology and global regulations is crucial. The following five topics, in particular, require additional discussion: regulatory and compendial changes, automation, difficult-to-inspect products, inspection control and monitoring strategies and updated requirements for container closure integrity testing.

Recent Regulatory and Compendial Changes

A review of data found on the U.S. FDA website shows continuing recalls associated with visible particles in injectable drug products. While the number of such recalls peaked in 2014, they continue to occur. The variety of particle types and companies involved suggest multiple root causes, which means no single corrective action is enough. Robust visual inspection processes are required to provide critical information to drive continuous process improvement and guard against significant process deviations.

Guidance on inspection methods and requirements can be found in global pharmacopeias. The United States Pharmacopeia (USP) published General Chapter <790> Visible Particulates in Injections covering inspection conditions and acceptance criteria in 2014, followed by <1790> Visual Inspection of Injections in 2017. Here, inspection conditions were harmonized with the European Pharmacopoeia (Ph. Eur.). Acceptance criteria based on widely used acceptance sampling plans were also established and Ph. Eur. published an update to its Chapter 2.9.20 Particulate Contamination: Visible Particles in 2018 which will become effective in 2019. In 2018, Ph. Eur. also published a draft of a new “non-mandatory” Chapter 5.17.2 Recommendations on Testing of Particulate Contamination: Visible Particles. This chapter, when finalized, will provide further guidance on complying with EU inspection requirements.

Beyond USP and Ph. Eur., the Japanese Pharmacopoeia (JP) updated their Chapter 6.06 Foreign Insoluble Matter in 2016 to harmonize inspection conditions with the USP and Ph. Eur. All these actions have brought global expectations for visual inspection closer together; however, differences—especially in acceptance criteria—continue to exist.

In 2017, the European Commission published a draft revision to Annex 1 Manufacture of Sterile Medicinal Products of the EU GMP guidelines. This covered many important topics including environmental monitoring, filtration and sterilization, as well as the finishing of sterile products. This latter section expanded the requirements for visual inspection, including prohibiting use of visual inspection to ensure container integrity for all container types. Further expectations were established on inspector qualification, alternative method qualification, use of defect libraries and trending of inspection results. An update regarding implementation and/or a revised draft is anticipated in 2019.

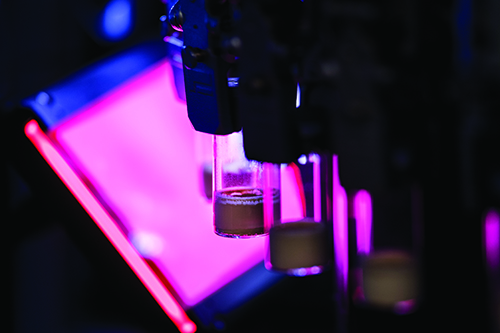

Automated Inspection

Automated visual inspection has been constantly evolving since its emergence in the pharmaceutical industry four decades ago. Advances in sensor technology and new artificial intelligence (AI) algorithms, such as deep learning, are likely to reshape visual inspection. Since the introduction of automated visual inspection with charged coupled device cameras and linear array sensors in the late 1970s, industrial PCs and image processing algorithms in 1980s, faster processing and machine capacities in the 1990s and compact and robust LED lighting in 2000s, many innovations have greatly enhanced the capability of automated inspection machines.

Improved illumination is a critical element for advancements in automated visual inspection. Last year saw development of multispectral lighting and structured color lighting methods that offer improved specificity, better discriminating true defects from artifacts such as air bubbles—a common cause of false rejects. Spectral illumination beyond the visible range, such as in the near-infrared region, can support the inspection of difficult-to-inspect products such as lyophilized cakes.

Recent advances in image processing algorithms can now analyze particle trajectories inside parenteral containers, again with the goal of differentiating true contaminating particles from air bubbles.

Deep learning’s emergence is likely to reshape automated visual inspection. The potential of deep learning was first established in 2012 using an Alexnet neural network that achieved previously unmet accuracy in image classification. Proof of concept for deep learning was presented at the 2018 Visual Inspection Forum in Berlin, showing that complex parenteral defects, such as cracks and particles, were readily detected (detection rates > 99%) and correctly classified (false reject rate < 1%) with this approach.

Deep learning also brings with it several questions:

- How do we validate these inference models?

- Will human inspection remain the reference method for visual inspection?

- What will regulators require to gain confidence in these models?

- Will we move from supervised to unsupervised learning algorithms?

Answering these requires close cooperation among machine builders, industry users and regulators. PDA is a unique organization that can help drive this change.

Difficult-to-Inspect Products

The 100% visual inspection standard has been established by design and recognized by global pharmacopeias as an additional control mechanism for particulates and other defects in sterile injectable products. This unit level inspection is a critical control point for removal of any visually detectable and undesirable/nonconforming units to ensure overall batch quality. But there are many dosage forms that make it challenging to detect common defects such as visible intrinsic or extrinsic (foreign) particulate matter. This can be due to product formulation or container type.

These difficult-to-inspect products are not able to take full advantage of the detection and removal process (notably for particulate matter) that is provided by an effective 100% in-process inspection. Therefore, undetected visible particulates may be present in the batch. Final acceptance sampling, i.e., acceptable quality limit (AQL) inspection, may not meet pharmacopeial or regulatory agency expectations. In a worst-case scenario, particulate matter in difficult-to-inspect product goes undetected by both 100% and final AQL inspection and is then released to market. Technical Report No. 79: Particulate Matter Control in Difficult to Inspect Parenterals focuses on a lifecycle approach to supplemental or destructive testing methods as part of a robust difficult-to-inspect product quality process for parenterals.

Examples of difficult-to-inspect dosage forms include products such as opaque and deeply colored solutions, lyophilized cakes, powders, concentrated suspensions and emulsions. Examples of difficult-to-inspect container types include amber vials, plastic syringes, blow-fill-seal ampoules, flexible bags and specialty containers such as some cartridges and medical devices. Difficult-to-inspect products such as these require some form of supplemental analysis or destructive inspection or testing and monitoring to ensure the product meets not only the USP definition of “essentially free from visible particulates,” but also the harmonized subvisible particle acceptance criteria found in the USP, Ph. Eur. and JP. To accomplish this, a lifecycle management approach that includes data from destructive inspection testing using a small sample from each batch along with a robust monitoring/trending strategy is essential in detecting, identifying and minimizing particulates.

Inspection Control and Monitoring

Control of visible defects requires inspecting each unit to remove noncompliant ones; 100% visual inspection is not the only point where product quality is assessed. A robust inspection process also includes a final check of lot quality. Here, a sample from accepted units is tested again prior to lot release. For difficult-to-inspect products, supplemental testing is also performed as required. Inspection results (defect counts or rate) are compared against historical values (reject analysis and trending) in order to ascertain that the process remains in control.

These additional functions are expected and referenced in USP <790> and <1790>. In <790>, “a complete program for the control and monitoring of particulate matter remains an essential prerequisite” when using acceptance criteria. USP <790> focuses on visible particles, but the requirements associated with particle defect control and monitoring should be extrapolated to include other defect categories/classes to ensure all aspects of the parenteral manufacturing process are evaluated for abnormal results or special cause influences—an expectation of GMP.

AQL inspection involves sampling inspected units and performing a quality control inspection to infer, at minimum, the overall batch quality in terms of critical, major and minor defect rates. Additional categories (such as particulates) may also have acceptance criteria associated with the inspection; USP <790> testing can be performed as part of this inspection. Sample size and acceptance criteria should be based on ANSI/ASQ Z1.4 (or ISO 2859-1) and AQL ranges for these categories are suggested in USP <1790>. The acceptance number for critical defects is commonly set to zero. Alternative sampling plans with equivalent or better protection are also permitted. This AQL inspection provides continuous monitoring of the visual inspection process. Any defects found in the AQL inspection should be reviewed to determine if the visual inspection process is deficient or if the missed defects can be explained by the probabilistic nature of inspection. The detection of any critical defect is generally considered a failure with further investigation and lot remediation (i.e., reinspection) expected.

After lot quality has been evaluated, all defects found inspections should be summarized into logical groups and compared against historical results and other factors (reject analysis and trending). This provides an opportunity to determine if any batch has abnormal defect rates compared to historical batches. When batches exhibit abnormal defect rates, an investigation should determine if the normal inspection process can handle the increased defect rate(s) and if this is a special cause variation for which a CAPA should be undertaken to improve the process.

There are many considerations that must be addressed in order to have a compliant 100% visual inspection process. At the same time, an obligation exists to verify the effectiveness of that inspection, and to use the data collected to continuously improve inspection processes.

Container Closure Integrity Testing

Container closure systems should maintain the sterility and product quality of their contents throughout their shelf life. Container closure integrity testing boasts a long history, but discussion has been heightened by two developments since 2016: USP <1207.1> Package Integrity Testing in the Product Life Cycle – Test Method Selection and Validation and the EU Annex 1 draft. Both have stimulated a broad discussion on future implementation of container closure integrity testing. The short statements in Annex 1 still require some interpretation, compared to the very detailed USP recommendations, yet they may seriously impact current practice. The new requirement for routine deterministic testing of a sample from every lot of conventional containers (those not fusion-sealed) by a method other than visual inspection will require new testing or increase the number of samples for testing. Traditional tests like blue dye/microbial ingress testing typically involve tens of samples, while commonly used acceptance sampling plans typically require testing hundreds of samples, depending on the size of the batch.

Many different methods are available to perform container closure integrity testing. USP <1207> divides the methods into deterministic and probabilistic categories. Some of the most common deterministic methods used today include:

- Electrical conductivity and capacitance test/high voltage leak detection

- Spectroscopic methods/laser headspace analysis

- Vacuum decay

- Mass extraction

- Pressure decay

These methods are most suitable for in-line, 100% inspection, or benchtop instruments for development or testing a statistical sample from the batch.

During method development, a preliminary method is chosen and qualified. Target acceptance criteria and leak testing parameters should be established and optimized. USP <1207.1> qualification trials should be performed to demonstrate that the method can pass validation. Positive and negative controls need to be created for the test in order to be compliant with regulations. The controls should be designed in accordance with the container closure system design, materials of construction, potential package failure modes and impact to product contents on test results. Container closure integrity test methods must be validated for the specific drug-product package. The validation of the leak test method is required to demonstrate test method precision, accuracy, range, robustness and detection limit.

Conclusion

The methods used to perform visual inspection and container integrity testing continue to evolve along with ever-changing compendial and regulatory expectations. Keeping current in these developments is critical in order to implement and maintain a compliant inspection process and consistently manufacture and deliver high-quality injectable medicines.

[Editor’s Note: The PDA Letter editors thank the planning committee behind the 2019 Visual Inspection Forum for contributing this article].