MAbs Require Ongoing Dialogue

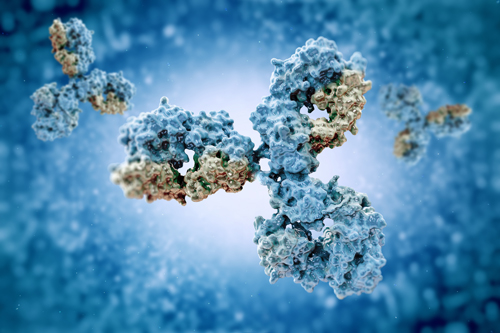

Since the mid-1980s, when the first monoclonal antibodies (mAbs) were launched to treat human diseases, this product class has witnessed tremendous success. MAbs and mAb-derived products are now routinely used to treat patients for a variety of deadly or debilitating diseases. Many more compounds are currently in various stages of clinical development for the treatment of cancers, infections, inflammatory/autoimmune diseases, and other disorders. Many mAbs have reached blockbuster status. Therapeutic success, in turn, has spurred innovation in the technical development and manufacturing of mAbs. The antibody structure now serves as a framework to create related molecular entities, such as fragments, Fc-fusions, bispecifics, and antibody drug conjugates, with the goal of optimizing therapeutic potential. Scientific advances in molecular biology have enabled the transition from murine to fully human mAbs, thus, reducing the risk of unintended side effects.

Improvements in expression systems and the development of novel cell substrates have boosted titers, and efficiency gains have been realized in manufacturing by adopting platform processes for upstream and downstream operations. Many mAb manufacturers were early adopters of Quality by Design (QbD) principles.

Years of accumulated process knowledge, platform approaches, and application of QbD-enabled control strategies have enabled solutions for adventitious agent clearance, and even elimination of routine testing for certain impurity types.

Despite these achievements, changes in regulations and advances in in silico and computational technology continually drive the need to reexamine existing practices and identify opportunities for improvement.

In 2008, PDA launched the first of a series of workshops on mAbs to sustain an ongoing dialogue between industry and regulators. This dialogue was initiated after publication in 2007 of the draft EMA guideline, Development, Production, Characterization and Specification for Monoclonal Antibodies and Related Products. PDA had provided comments to the draft guideline and was subsequently invited to meet with the Biologics Working Party to discuss industry feedback. The need to discuss current and emerging topics on a periodic basis emerged. PDA’s mAb workshops over the years have covered relevant topics such as QbD, quality attributes, immunogenicity, control strategy, and innovative manufacturing approaches.

This year marks the 10th anniversary of this series of successful workshops. PDA Europe and the mAb workshop planning committee are pleased to announce the theme of this year’s mAb workshop: “Manufacturing & Analytics Considerations for Antibodies and Related Products – A Decade of Progress.” The objective of the workshop is to highlight achievements reached in the manufacturing and analysis of mAbs and related products over the past 10 years and explore innovative technologies and approaches that will influence the next decade of mAb development and manufacturing. As in previous years, the workshop program features a session on recent regulatory developments, featuring renowned European regulators, as well as case studies and panel discussions on upstream and downstream process development, control strategy design, antibody-related products, and technological innovations presented by industry leaders.

This year, in addition to being the 10th anniversary, the conference will also be part of the PDA Europe Exchange Series. This new format intends to give attendees the chance to “Meet, Exchange and Connect” with other professionals from around the globe by also providing access to the 2nd PDA Europe Particles in Injectables Conference, which will take place at the same time, in the same location.

Learn more about the Workshop on Monoclonal Antibodies and Particles in Injectables Conference.