Robotics and AI Have Much to Offer Pharma

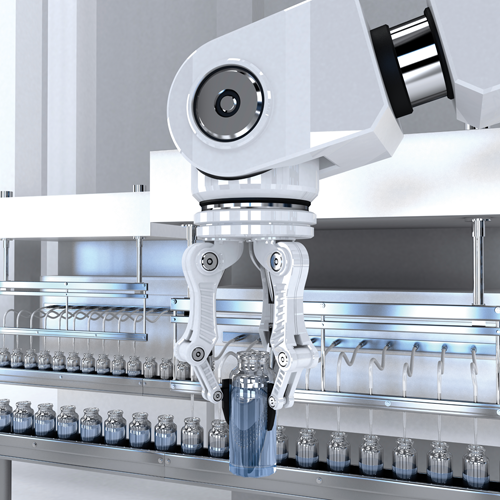

New doors are open for pharma manufacturers. Far-reaching innovations in this exciting area include new operational processes, robotics, automation and complete digitalization.

What does this mean for the pharma industry? Are these new technologies even applicable to pharmaceuticals? Is pharma different from other market segments? And most importantly, what do the regulators think?

It is time for pharma to embrace the digital robot “fab”—a term from the artificial intelligence (AI)/robotics world that refers to a factory that combines robotics with AI and full digitalization.

Currently, pharma manufacturers are stepping slowly into robotics and AI. But equipping one filling line with only one to three robots is limiting as it fails to take advantage of sweeping manufacturing possibilities. It must be recognized, that far more technology is available for pharma than manufacturers realize. The development speed is huge, and suppliers are ready with convincing solutions.

The author will lead the Digital Robot Pharma Fab preconference workshop. This one-day workshop will combine lectures with hands-on learning opportunities for those interested in robotics and AI. There will be case studies, as well, from other industries along with regulatory viewpoints.

In addition, the following 4th PDA Europe Annual Meeting will feature breakout sessions on virtual reality, robotics, blockchain, AI and big data.

Pharma needs a disruptive approach that assesses risks and opportunities while merging concepts. Provocative ideas need to be introduced. At the same time, quality cannot be ignored. Total Quality Control, zero errors and right-first-time concepts along with shortened commissioning times and flawless validations are requirements which must be met. Fortunately, these challenges can be overcome with the help of these new technologies. Innovative technologies offer significant opportunities to reach quality and zero loss objectives.

Data Critical to Pharma Innovation

The future of pharma will be driven by data. Comprehensive measurement recordings and their results will determine control vectors in manufacturing. This high volume of data requiring extensive analysis will rely on a backbone of consistent and comprehensive quality.

The gathering of this “big data” leads to several questions. What becomes of a pharma production module after reviewing real-time developments? Taking advantage of this intelligence leads to the success that turns an average company into a market leader.

Robotics, AI and digitalization are a disruptive combination that provides pharma manufacturing strong momentum. These technologies require the industry to fully understand their capabilities and their next generation potential. Plus, they are ready as robust and reliable robotic systems (1).

Robotics will also be part of pharma’s transition into a “pharma fab.” But is pharma ready?

Additional technological advancements to consider are more flexible manufacturing options that go beyond continuous manufacturing and laboratory automation.

A new world awaits pharma. And the industry can no longer wait to take ad-vantage of robotics and AI. Waiting is an unjustifiable economic and product quality risk in today’s environment. Technology evolves at a faster rate now more than ever, and the more pharma waits, the more it will fall behind. Pharma manufacturers need to be at the forefront of change.

Reference

- Bultmann, J.M. “Prefilled Syringe Manufacturing Moves Away from Hands-On Approach.” PDA Letter 53 (October 2017) 28–31.

Martin Düblin is a mechanical and process engineer. For more than 25 years, he has been involved in major strategic projects across the globe, including in robotics, AI and digital solutions.

Martin Düblin is a mechanical and process engineer. For more than 25 years, he has been involved in major strategic projects across the globe, including in robotics, AI and digital solutions.